Birchenough Bridge

Memories of the building of of Birchenough Bridge

Inner Page of Cover

Forward.........

IT has given me great pleasure to be asked to contribute a foreword to this booklet which is being issued as a Souvenir of the opening of the

Once again we acknowledge the debt we owe to Alfred Beit, the far-seeing provisions of whose Will have made the building of this Bridge possible, a Bridge which will, I am sure, prove of inestimable benefit to the Eastern Districts of the country by bringing them into closer touch with their markets and with the rest of Rhodesia, and will facilitate the flow of tourist traffic to one of the most beautiful and fertile portions of the colony.

Prime Minister

The

|

|

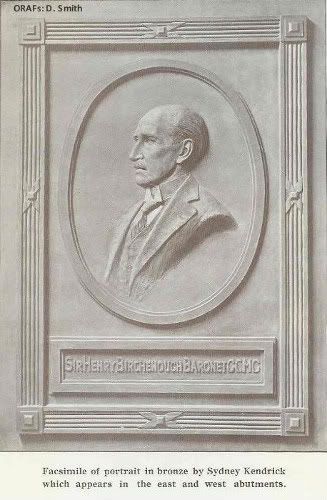

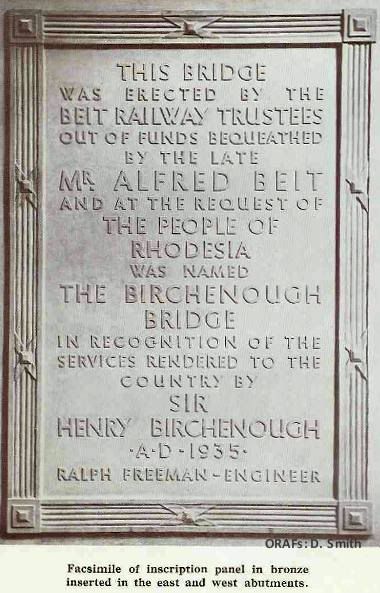

THE magnificent bridge spanning the Sabi River, a gift to the Public of Southern Rhodesia from the funds of the Beit Trust has, at the request of the people of Rhodesia, been named " THE BIRCHENOUGH BRIDGE" in recognition of the services given to the country by Sir Henry Birchenough, Bart., G.C.M.G., the Chairman of the Beit Railway Trust and President of the British South Africa Company. Portraits in bronze of Sir Henry Birchenough, by Mr. Sydney Kendrick, and inscription panels in bronze have been inserted in the east and west abutments.

The bridge was built to give the people residing in the eastern districts access across the

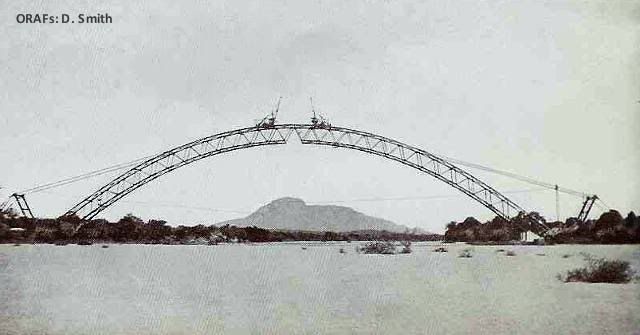

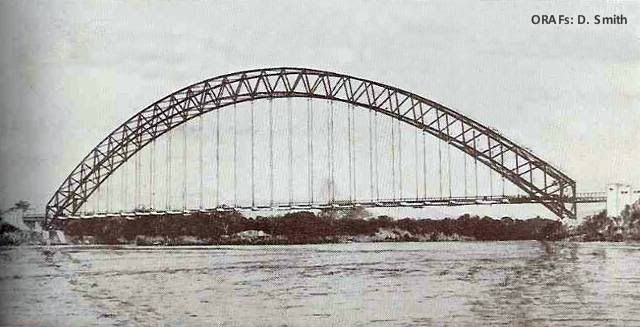

The bridge crosses the Sabi River with a single arch which rises to 280 feet above the river, and is 1,080 feet in length, a span which is exceeded by only two other arch spans:—-the great bridge crossing Sydney Harbour, and the Bayonne Bridge over the Kill van Kull Creek, south of New York.

The

The bridge is the first long-span bridge to be constructed in the

The roadway has a width of 18 feet and is designed for heavy-type Colonial loading. Footways are formed on either side of the road so as to allow for the uninterrupted passage of two lines of traffic.

The total weight of steel is 1,500 tons and it is noteworthy that this is the same weight as that of the

In the combination which the design provides of an exceptional span with light weight and small capital outlay, the arch span is unique in bridge construction.

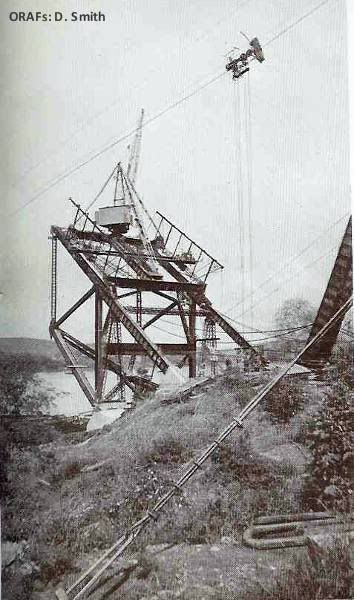

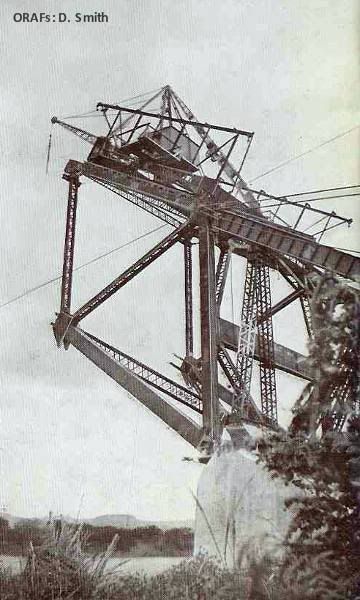

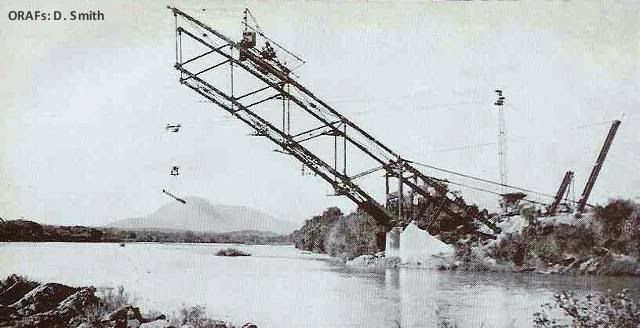

The bridge was erected by the same process as that used for the Victoria Falls Arch and subsequently for the

Material was delivered to the west bank of the river by road and the rapid and completely successful transport of the heavy and cumbrous pieces of material under conditions of exceptional difficulty, was an achievement for which great credit is due to the Rhodesia Railways Road Transport organisation and to the Roads Department of the Government of Southern Rhodesia. The steelwork for the east side was carried across the river by a cableway.

Foundations were commenced in April 1934 and were ready for steelwork in November. The arch span was completed on June 17th, 1935, and the concrete roadway was practically complete at the end of September, 1935.

The only work then remaining was unimportant auxiliary construction and painting. The whole of the works were finished so as to enable the bridge to be opened to traffic on December 20th, 1935, the time occupied by the entire construction being 20 months.

The contractors for the supply of steel, manufacture of steelwork, and erection, were Dorman Long & Company, Limited, of

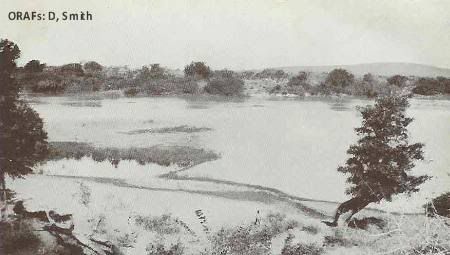

Bridge Site: Sabi River before work was commenced.

April 1934

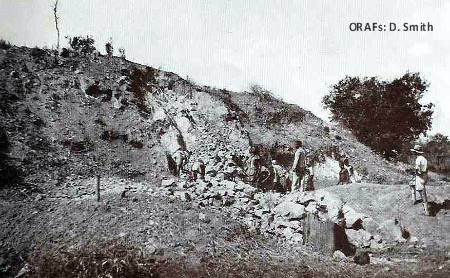

East Bank: Excavation work started on the skewback foundations.

May 1934

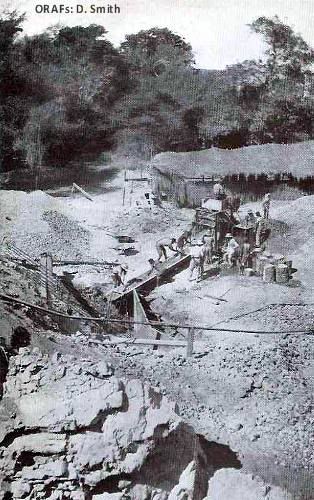

East Bank.Concrete work commenced at the south-east skewback.

August 1934

Bearings in position ready to be concreted.

September 1934.

East Bank. Skewbacks and bearings completed.

October 1934

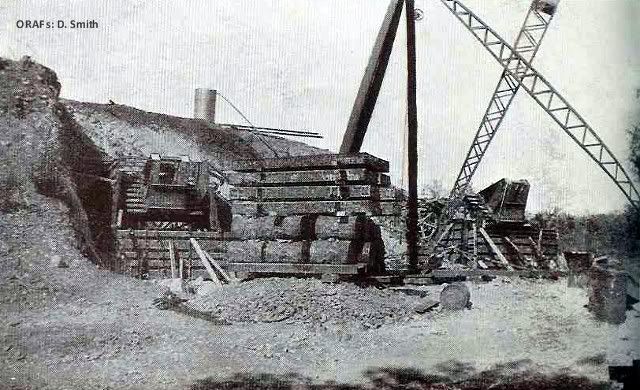

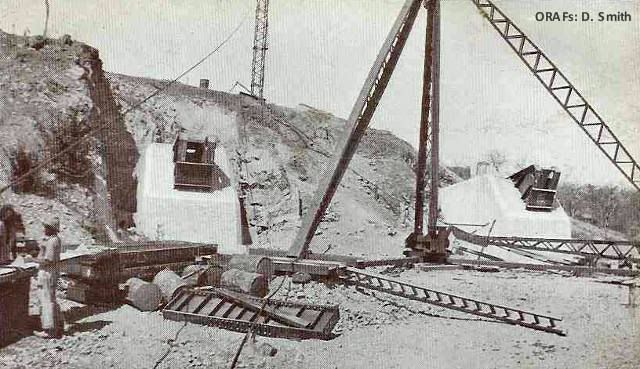

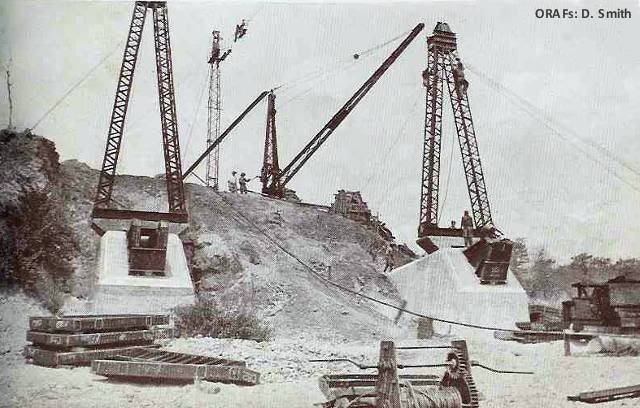

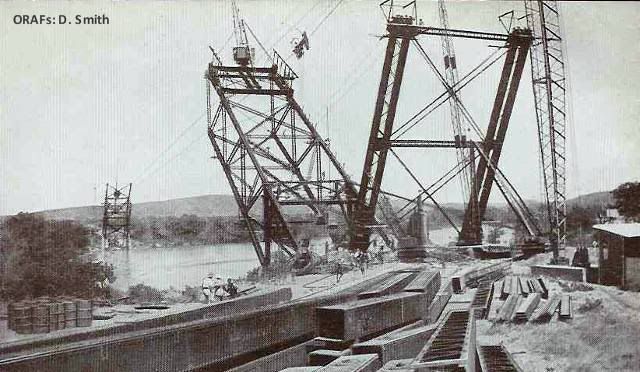

East Bank. Erection of temporary ramp at back of skewbacks on which creeper

crane was erected for travelling up on the arch.

November 1934

East Bank. Skewbacks and bearings completed.

October 1934

East Bank. Erection of temporary ramp at

back of skewbacks on which creeper crane

was erected for travelling up on the arch.

November 1934

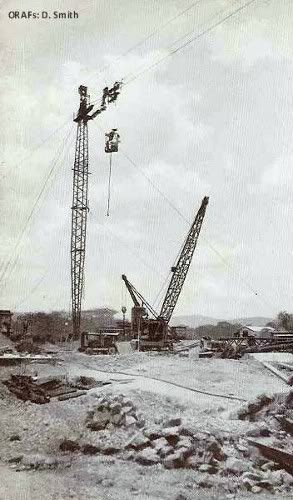

East Bank. Commencent of erection of steel-work.

December 1934

East Bank. Furst panel completed with crane on top chord.

January 1935

Driving the First Rivet.

22 January, 1935

West Bank. First panel completed.

January 1935

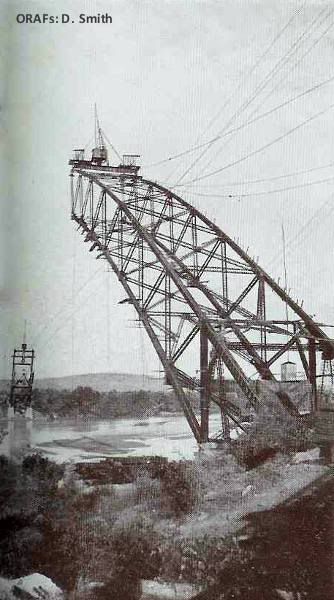

Position of steelwork of arch.

End of February 1935

Position of steelwork of arch.

End of March 1935

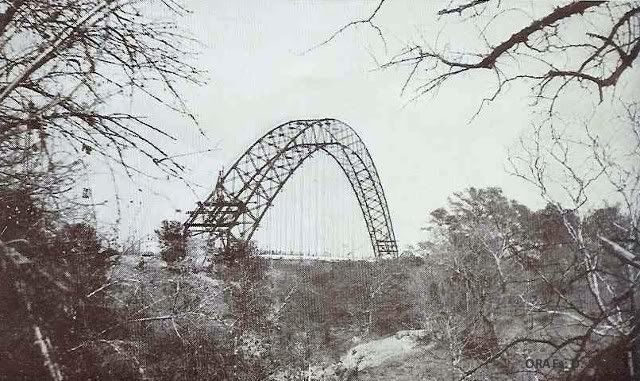

West Bank. Position half-arch.

End of April 1935

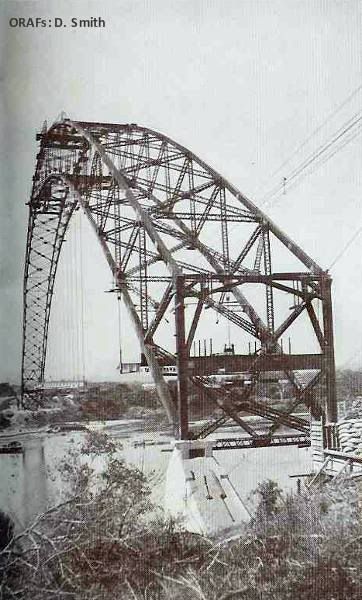

Position of arch, early in June 1935

Closure of arch, early morning.

17th June 1935

Arch completed.

July 1935

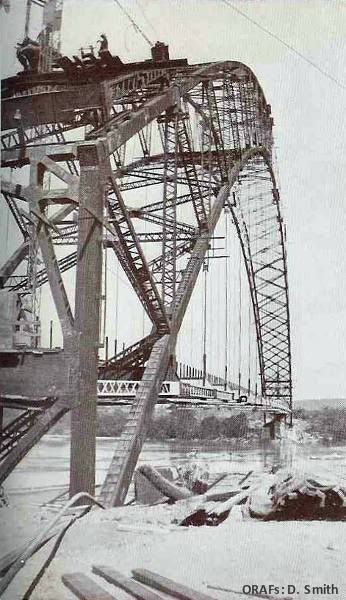

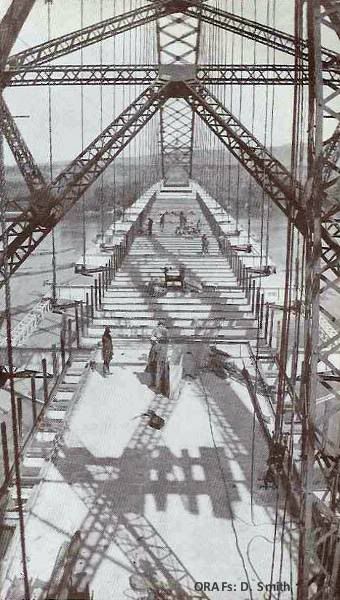

View of arch from west to east. Deck in process of construction.

Middle of July, 1935

West Bank. View of arch from west to east showing completed

steelwork of deck and approach span

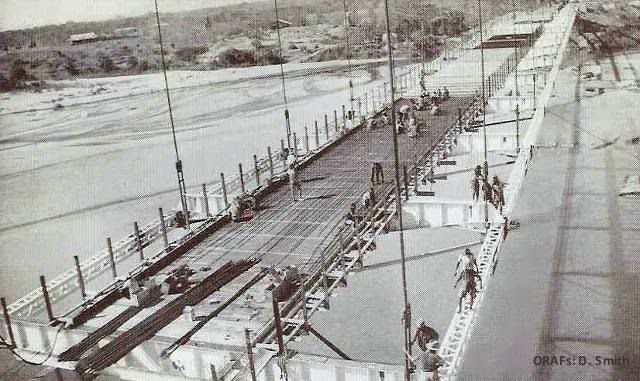

View of deck looling east. Placing reinforcement in concrete roadway in the foreground.

August 1935

View of Bridge approaching from Umtali.

August 1935

View of Bridge. North side looking west.

Creeper cranes being dismantled.

August 1935

General View of roadway under construction.

September 1935

General view of completed bridge with approach spans and abutments.

December 1935

Re-compiled by Eddy Norris from the brochure that was made available to ORAFs by

Diarmid Smith. Thank you Diarmid

Labels: Birchenough Bridge. River

25 Comments:

Tim Musto Writes:-

Was last there on my 1000cc Suzuki, doing a tour of Chipinga, Chimanimani etc.

Hot as hell from what I recall.....and just sand in the Sabi !!

Brilliant engineering. I bet it will see many more decades, if not centuries.

Neil Baalbergen

As a matter of interest, in his book "My Life Was A Ranch", DM Somerville describes the difficulties of travel before the bridge was built. He also devotes a couple of pages to the part he played in helping locate the eventual site of the proposed bridge. (DM Somerville won the Umtali North seat in the 1933 elections, representing the Reform Party).

Made a round trip to the Chimanimani form Mutare - missed a turnoff and ended up at Birchenough. Was a very long day - but what a wonderful sight. Hot yes, but magnificent. Tad bit of water in the river - was before Cycolne Eline. Would LOVE to see if there are pics of the river after that cyclone

I used to go to Birchenough and the Hot Springs when I was training as a nurse, often as a means to getting used to sleeping at night instead of the day after night duty stints. What a breathtaking view that bridge is and at the time it was built an engineering work of art. I daresay its not being maintained the way it should be....which if it is the case will be great tragedy...

In June '52, an American tourist in the Birchenough Hotel bar bet me £5 I couldn't climb over it. I did, wearing Inkomo Camp army boots which, with steel studs, were not ideal. The Yank paid up and the proceeds were drunk by me and everyone in the bar. I weaved a somewhat erratic course on my AJS5OOcc from there on the strip road to stay with the Bridges family on Devuli Ranch. At the turn off, I encountered miles of sand, fell off and went to sleep until the beer had worn off, telling my hosts I had got lost. Those were the days.

What a magnificent site for the first time when i went there for a school trip!Though my home is located a couple of miles North,i had never been there.Thanks for the Headmaster of Betera High School,my Dad&My Mom who made the trip successful.Wonderful architecture by his Majesty Sir Ralph Freeman,a blessed hand by sir Henry Birchenough and all those who participated for the project to be a success!May their soul rest in peace and to those who are still surviving God bless you!

Thanks for everyone who contributed towards this mastered structure.Munodadisa and may your soul rest in peace

This structure linked trade between province and districts in our country there by promoting trade domestic and international .Thanks to Sir Birchenough and the rest of his team for putting our country on the map and promoting tourism and I hope this will last for decades if not centuries.

beautiful thing l comment. l am happy its in my country Zimbabwe. have been there once and l enjoyed walking across it. My ancestors played a big part in the construction of this creature l hope they benefited something out of it as it was made during the colonial era

I wonder how many millions of years of evolution will be required before the stone-age primitives in subaharan Africa will be capable of building such a bridge.

Pamwe vamwe veganda redu ndivo vaishandiswa zvavo pasina muripo

I'm sure the state of the Bridge is not well looked after and with the ongoing flooding of Sabi River if not we'll maintained the worst will come.

An awesome structure. My Dad, Harry Went was working for the Rhodesia Railways (not sure of the year, will have to do some research)and it was calculated that if a extreme freeze up occurred in winter a major problem would occur!

The bridge deck is anchored at one end and the other end rests on 'slide- plates' and as the bridge heats up in the day and cools at night, the one end slides along the plates as it expands and contracts. It was calculated that in the event of an extreme freeze, the sliding end could possibly drop off the slide-plate then when the bridge heated up in the day, it would not be able to slide and the bridge would buckle and be badly damaged!

It was decided to move the whole bridge 3/4 of an inch (19mm) towards the slide-plate end!!

Dad in a Railways Team, was involved in that process. During the cold night, wedges were rammed into the 'space' at the slide end and the anchor bolts were loosended at the other end then after the heat-up during the day, the bridge expanded then the bolts were tightened. When it cooled again that night, the wedges were able to be hammered in a fraction of an inch further then the whole process was repeated. In this way the bridge was moved. I seem to recall it took a week or two to achieve the desired re-positioning! How amazing.

We had photos of Dad at work and standing on the top of the bridge which he climbed over at least once.

Interesting ............. especially as today is 'Father's Day'. Well done Dad.

Ant Went in Mutare (Umtali)

An awesome structure. My Dad, Harry Went was working for the Rhodesia Railways (not sure of the year, will have to do some research)and it was calculated that if a extreme freeze up occurred in winter a major problem would occur!

The bridge deck is anchored at one end and the other end rests on 'slide- plates' and as the bridge heats up in the day and cools at night, the one end slides along the plates as it expands and contracts. It was calculated that in the event of an extreme freeze, the sliding end could possibly drop off the slide-plate then when the bridge heated up in the day, it would not be able to slide and the bridge would buckle and be badly damaged!

It was decided to move the whole bridge 3/4 of an inch (19mm) towards the slide-plate end!!

Dad in a Railways Team, was involved in that process. During the cold night, wedges were rammed into the 'space' at the slide end and the anchor bolts were loosended at the other end then after the heat-up during the day, the bridge expanded then the bolts were tightened. When it cooled again that night, the wedges were able to be hammered in a fraction of an inch further then the whole process was repeated. In this way the bridge was moved. I seem to recall it took a week or two to achieve the desired re-positioning! How amazing.

We had photos of Dad at work and standing on the top of the bridge which he climbed over at least once.

Interesting ............. especially as today is 'Father's Day'. Well done Dad.

Ant Went in Mutare (Umtali)

Whew! I grew up in the Birchenough Bridge area with no idea how that amazing piece of Engineering was put up. Thank you for the information. However, I am shocked to see that Photobucket is blocking the images. The pictures had more stories to tell. Please admin, if you could assist by accessing your photobucket account and downloading the pictures for re-sharing. Pretty please! Jevias Chimana - Mutare

What plans are in place towards maintenance of the bridge if I may ask admin?

My home

Kanyi. Thanks to everyone working towards the proper use of the bridge. What a wonderfull piece of work.

What is the state of the bridge now due to the recent cyclone that ripped the entire Chipinge n Chimanimani districts? Im sure maintenance measures must be put in place to avoid major catastroph.

AWESOME ENGINEERING

It is extremely chock-full of useful information. vape attic olathe

Taura hako

The Birchenough Bridge is a remarkable landmark that showcases stunning architecture and engineering. It's interesting how the bridge has become a point of interest for both locals and tourists, often featured in Google searches for its picturesque views and historical significance. If you're planning to visit, make sure to check Google for directions and travel tips—it's definitely worth the trip! What a perfect spot for photography!

One of Zimbabwe's most famous engineering achievements, the Birchenough Bridge, is a testament to structural genius and inventiveness. Knowledge of these landmarks helps motivate students pursuing engineering or architectural degrees. Services such as Lab Report Writing Help UK can help you communicate technical findings in an exact and straightforward manner if you're working on relevant coursework and need assistance.

This comment has been removed by the author.

Post a Comment

Subscribe to Post Comments [Atom]

<< Home